Features of Fiber Laser Cleaning Machine

- Non contact cleaning

- User friendly features, easy to use

- High cleaning efficiency, saves time

- Long life, Maintenance Free

- Precision positioning, selective cleaning, desired cleaning area can be applied to the work piece.

- Safe & Environment friendly.

- Easy to operate

- Portable

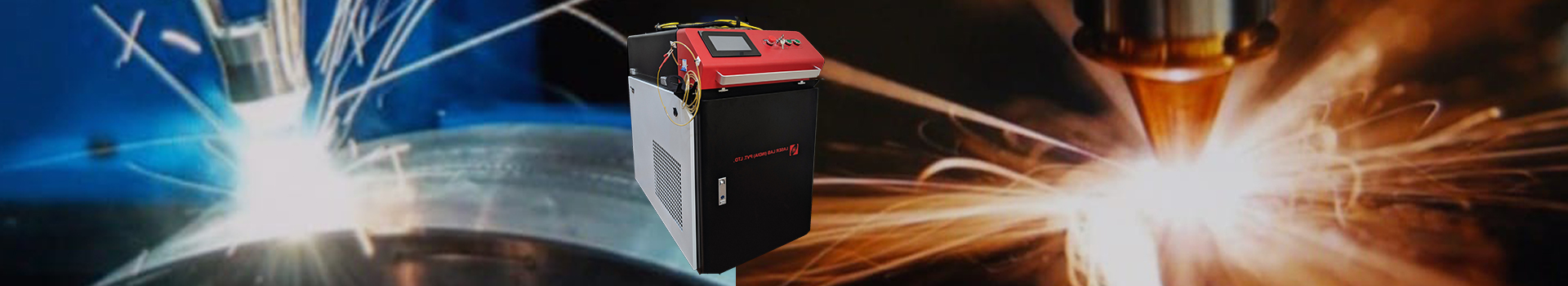

Laser Cleaning Machine in India – Advanced Surface Cleaning Technology

Looking for a reliable Laser Cleaning Machine in Delhi NCR? Laser Lab India offers high-precision fiber laser cleaning solutions for industrial applications such as rust removal, paint stripping, grease cleaning, and surface preparation. Our cutting-edge technology ensures non-contact, eco-friendly cleaning without damaging the base material.

Why Choose Our Laser Cleaning Machines?

- Rust, Paint & Contaminant Removal: Effectively removes rust, coatings, and unwanted layers from metal surfaces.

- Eco-Friendly & Chemical-Free: No hazardous chemicals or waste, making it a sustainable choice.

- High-Speed & Precision Cleaning: Achieve faster and more accurate cleaning results with fiber laser technology.

- Minimal Maintenance: Low operating costs with long-lasting laser sources.

- Portable & Industrial-Grade Options: Available in handheld and automated systems for various industrial needs.

Applications of Laser Cleaning Technology

Our laser cleaning machines are widely used in industries such as:

- Automobile & Aerospace – Surface preparation and paint removal.

- Annilox Roller Cleaning.

- Metal Fabrication – Oxide and residue cleaning for welding pre-treatment.

- Heritage & Monuments – Non-abrasive cleaning of historical artifacts.

- Electronics & Electrical – Precise cleaning for sensitive components.

Get the Best Laser Cleaning Machine in India

As a leading supplier of laser cleaning systems in Delhi NCR, Laser Lab India provides top-quality machines with excellent after-sales support. Contact us today for a free consultation and demo of our industrial laser cleaning machines.

📞 Call: +91 9716054356 | 📧 Email: sales@laserlabindia.com

Technical Parameter:

| Model | LLI-LC-1000/ LLI-LC-1500/ LLI-LC-2000C |

| Power | 1000W/1500W/2000W |

| Source | CW |

| Cleaning system | Touch Screen Operated |

| Chiller | Inbuilt |

| Beam Length | 0-100mm |

| Wavelength | 1064nm |

| Wave frequency | 0-3000HZ adjustable |

| Focusing lens | 500mm cleaning |

| Power supply | AC220V 50\60HZ |

| Cooling method | Water cooling |

WHY CHOOSE LASER LAB INDIA

Pioneer laser company in India to provide complete Industrial Laser Solution

Established in 1995 by promoters with more than 30 years of experience in industrial lasers.

an ISO 9001:2015 certified company with CE Certified machines.

Rich customer base all over India as well as Internationally.

Our satisfied customers are ranging from Large Industries & MNCs, Government Organizations, Defense, Aero Space, R&D Centers, Premier Educational Institutions, Jewellery & Hall marking Centers, Creative start-ups, etc.

Complete onsite Installation & Training, Prompt Service Support by trained, experienced & dedicated engineers.